-

Jun 14, 2018

-

Jun 14, 2018

-

Jun 14, 2018

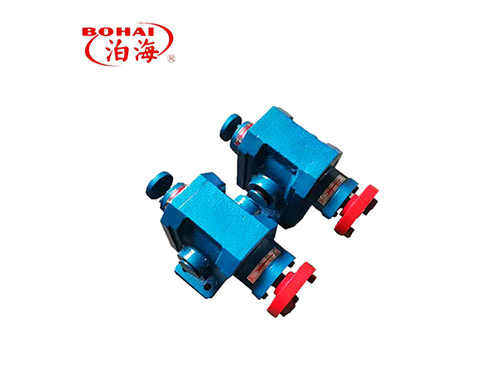

Kerosene transfer pump with valve

Kerosene transfer pump with valve is a kind of will conform to the conditions of pumping concrete through the horizontal or vertical laying of pipeline continuous conveyor to the pouring of concrete conveying equipment, construction site USES motor or diesel engine as power, widely used in concrete requirements, high grade, strict quality, long conveying distance high-rise buildings, municipal construction, electric power, energy, transportation and other civil and industrial buildings, Especially the construction of narrow site.

The performance characteristics of

1. This product adopts double pump, double loop open hydraulic system, the main pump oil circuit and S valve swing oil circuit are independent of each other, the use of the system is simple, components long life, higher reliability, while reducing the temperature of the system, and easy to judge and dismantle the fault.

2. Main pump oil circuit reversing adopts main reversing valve external control pilot decompression control.

3. The hydraulic system has safety overflow protection, and when the main pumping system overpressure, the oil pump pressure cut off automatically open.

4. Swing oil circuit adopts constant pressure oil supply combined with energy storage device, so as to reliably ensure large swing power and energy saving effect.

5. Pump group and valve adopt world famous brand, more reasonable, more reliable, easy to achieve stepless regulation of concrete throughput.

6. Hydraulic pipe adopts conical seal and pipe joint sealing material.

7. The pumping oil road adopts valve block to switch between high and low pressure, which is convenient and does not leak oil.

8. Adopt oil absorption and oil return filtration technology to avoid foreign matter entering hydraulic system. Further improve the reliability of hydraulic system and component life.

9. The hydraulic pipe adopts rubber hose.

14

Jun

Gear pump oil pump gear oil pump drive shaft can't bear any radial vertical force and lateral drive way, higher floor str...

14

Jun

The working pressure of high pressure gear pump refers to its output pressure.That is, oil must be built up to overcome r...

14

Jun

When the gear rotates, the melt into the suction chamber two gear tooth, with gear running, the melt from either side int...

14

Jun

Suitable for transportation of crude oil temperature is not higher than 140 ℃, oil, weak alkaline liquid syrup, yeast.I...