-

Jun 14, 2018

-

Jun 14, 2018

-

Jun 14, 2018

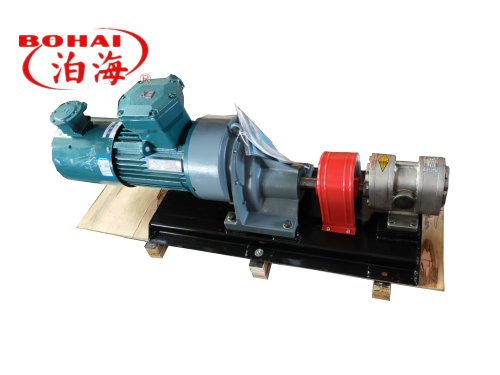

General knowledge of gear pump repair

Jun 14, 2018, 14:21:32

As the knowledge of gear pump repair increases with the application of time, gear pump will present a lack of pump oil, or even no oil problems, the primary reason is the excessive wear of relevant parts.The wear parts of gear pump mainly include automatic shaft and bushing, middle hole and shaft pin of passive gear, inner cavity and gear of pump shell, end face of gear and pump cover.When the primary skill target of smooth oil pump fails to meet the requirement after wear, it should be disassembled and differentiated to check the wear position and level, and the response method should be adopted for repair.

I. when the automatic shaft and liner of the gear pump are worn out, the joint clearance increases, which will inevitably affect the oil quantity of the pump.The normal common clearance can be restored by repairing the automatic shaft or bushing.If the automatic shaft wear is slight, the common clearance can be restored to the allowable limit by simply pressing out the old liner and replacing it with the standard size liner.If automatic shaft and bushing wear and severe joint clearance severe overweight, is not as long as change bushing, and automatic shaft also use chrome plated or vibration welding method will increase, its diameter and then grinding to specification size, a common requirement for recovery and bushing.

Two,Repair the crack of the smooth oil pump shell: the crack of the shell can be repaired by casting 508 nickel copper electrode.The weld must be tight and the hole in the element, and the plane error with the pump cover shall not be greater than 0.05 mm.Repair of wear and tear of automatic bush hole and driven shaft hole: after wear and tear of automatic bush hole, it can be used to eliminate wear and tear by means of hinge cutting, and then equipped with liner that is increased to response size.Driven shaft hole wear also to ream method to eliminate wear passed, and then according to the practice of the ream the hole size of driven shaft of pump shell lumen repair: the pump shell cavity after wear, general acceptance of the inner cavity set of method to repair, single filter will lumen enamel lined with iron or steel big bushing.After the insert, the inner cavity is honed to the required size, and the lining sleeve of the outstretched end surface is rubbed off to make it flush with the connecting surface of the pump shell.Repair of seat: pressure limiting valves are spherical and plunger valves.When the ball seat is worn, place a ball on the seat and tap the ball quietly with a metal rod until the ball valve fits tightly with the seat.If the seat wear is severe, you can first hinge to remove the abrasion mark, and then use the method to make it close.After the plunger seat is worn, a small amount of valve sand can be put in for grinding until sealing.

Three, pump cover repair repair in the plane of the task: if the plane wear small, pump cover task available manual grinding method to eliminate wear things, namely, put a little on the platform or plate glass valve sand, and then put the pump cover for grinding, until the wear part, distilling task looks flat.When the surface abrasion depth of pump cover exceeds 0.1mm, it should be repaired by turning first and grinding later.Repair of the automatic shaft lining sleeve hole of the bag cage of dust catcher: the repair method of the automatic shaft lining sleeve hole wear on the pump cover is the same as that of the automatic shaft lining sleeve hole wear of the shell.The wear of gear of gear pump is mainly at the tooth thickness, while the wear of gear end face and tooth top is relatively light.The gear is worn on one side at the tooth thickness, so the gear can be turned 180 degrees.When the end face of the gear is worn, the end face can be ground flat, and the connection surface of the smooth oil pump housing can be ground, so that the gap between the end face of the enveloping gear and the pump cover is within the limit of the specification.