-

Jun 14, 2018

-

Jun 14, 2018

-

Jun 14, 2018

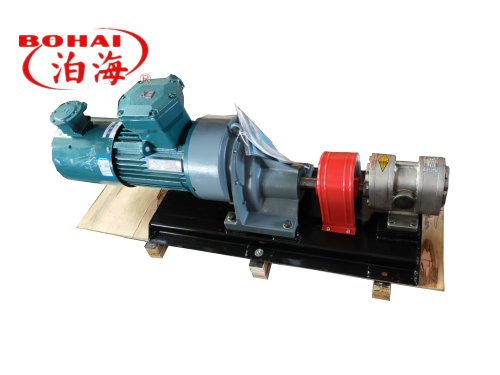

The service scope and structural characteristics of roots pump

Jun 14, 2018, 14:55:11

LC lutz pump scope of application:

Suitable for transportation of crude oil temperature is not higher than 140 ℃, oil, weak alkaline liquid syrup, yeast.It is suitable for medium with high viscosity, high concentration and high consistency with suspended substance or impurity.

Structural features of LC lotz pump:

This series of roots pump by the pump body, pump cover, shaft, gear, rotor, filling and capping parts, such as the roots pump belt transmission and gear speed reducer drive two forms, to reverse, equipped with skeleton oil seal on both ends of the shaft, middle oil return unit, in case of admission or leak.

The defects of roots oil pump:

1. Insufficient oil supply of oil pump or no oil pressure phenomenon: the working device is slowly hoisted, and the lifting device is trembling or unable to lift;Bubbles in the tank or tubing;The hydraulic system makes a "jacking and jacking" sound when lifting.When the tractor is started, the working device can be lifted. After the oil temperature rises high for a period of time, the lifting is slow or cannot be lifted.(1) the oil level of the hydraulic oil tank is too low;(2) not using hydraulic oil according to the season;(3) the inlet pipe is seriously blocked by dirt;(4) oil seal of oil pump driving gear is damaged and air enters the hydraulic system

2. Wear on the inner parts of the oil pump. Wear on the inner parts of the oil pump will cause internal leakage.The main part of internal leakage is the large leakage area between floating sleeve and gear end.This part of leakage accounted for about 50%~70% of total internal leakage.The volumetric efficiency of gear pump with wear leakage decreases, and the output power of oil pump is much lower than the input power.The loss is all converted to heat energy, thus causing the pump to overheat.If the combination plane is pressed tightly, the floating axle sleeve will suffer wear and tear due to a small amount of movement during operation. As a result, the lifting of agricultural tools will be slow or unable to be improved, and such floating axle sleeve must be replaced or repaired.

Rotary lobe pump, oil pump shell, back cover, gear box, bearing cover, bearing gland, driving shaft and driven shaft, rotor, drive gear, drive shaft and driven shaft sealing device, its characteristic is that the gear box body 3 for whole closed ring cylindrical, driving shaft and driven shaft through the bearing, bearing gland, seals, bearing cover, bearing gland and install connection on both ends of the gear box body around, two mutually meshing gear installed in the gear box right end on the driving shaft and driven shaft, on the right side of the pump casing is equipped with side board,On the right side of the pump shell 1 end plate which has outer ring connection sleeves and respectively with that of the driving shaft and driven shaft collar, the right end of the pump housing through its connection sleeves on the left side of the gear body docking bolt connection, two reciprocal rotor fixed respectively installed in the pump shell of the driving shaft and driven shaft end, on the back cover and the pump shell by bolts, the left side of the fixed connection in the pump shell on the right side of the collar set respectively has the driving shaft and driven shaft sealing device, on the right side of the sealing device on the driving shaft and driven shaft fixed with the oil slinger, respectively, set inside the right connection structure formation in the pump shell lumen,The oil inlet of the inner cavity and pump body is provided with a connected guide pipe.

When the inlet and outlet pressure of the pump exceeds the regulated pressure, the overflow valve overflows and the inlet pressure decreases.When the inlet pressure is too low, the oil pump will inject oil into the pressure tank, so that the inlet pressure will rise to the regulating pressure.The function of the two accumulators is to avoid the violent fluctuation of the inlet and outlet pressure of the pump and ensure the inlet and outlet pressure of the pump meet the working condition.

When roots pump a stroke on the movement, the electromagnetic switch, gas through one-way valve into the pump, when on the polished rod comes into contact with the travel switch, electromagnetic switch is closed, gas circuit impassability, then pump down stroke movement.Since its establishment, the company has been developing and growing with the strong support of colleagues from all walks of life and customers. It has many high, fine and advanced equipment and realizes CAD aided design and information management.The company has excellent equipment, advanced design, complete production and testing means, strong technical force and strong research and development capacity.All the members of the company are determined to take science and technology as the forerunner, take integrity as the aim, take quality as the basis, take customers as the god, keep improving and pursue forever.When the light rod comes into contact with the travel switch again, the electromagnetic switch is opened, the air circuit is opened, and the gas is supplied to the pump again.

Single-phase flow test device, mainly by the power cylinder, organic glass pump barrel and plunger, the hydraulic control system, is the core part of simulation test device for oil well pump, its most prominent feature is the use of the hydraulic control system drives the piston reciprocating movement up and down, heat pump has a stable, asphalt commutation quickly complete, simulated downhole conditions etc., can compare real simulation of the downhole working conditions and the flow of the liquid in the pump.

next:Hydraulic gear pump placement mode and its requirements