-

Jun 14, 2018

-

Jun 14, 2018

-

Jun 14, 2018

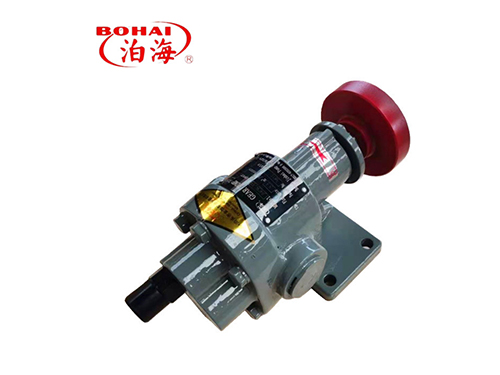

Gear pump series

Gear pump series that relies on the working volume change and movement formed between the pump cylinder and the meshing gear to transport liquid or pressurize it. It consists of two closed Spaces: two gears, pump body and front and back cover. When the gear rotates, the volume of the space of the gear off side increases from small to large, forming a vacuum, and the liquid is sucked in. The volume of the space of the gear meshing side decreases from large to small, and the liquid is squeezed into the pipeline. The suction cavity and the discharge cavity are separated by the meshing lines of two gears. The pressure of the discharge outlet of the gear pump depends entirely on the size of the resistance at the pump outlet.

Advantages: simple and compact structure, small size, light weight, good technology, cheap price, strong self-suction, oil pollution is not sensitive, large speed range, impact load resistance, convenient maintenance, reliable work.

Disadvantages: radial force imbalance, flow pulsation, noise, low efficiency, poor interchangeability of parts, not easy to repair after wear, can not be used as variable pump.

14

Jun

Gear pump oil pump gear oil pump drive shaft can't bear any radial vertical force and lateral drive way, higher floor str...

14

Jun

The working pressure of high pressure gear pump refers to its output pressure.That is, oil must be built up to overcome r...

14

Jun

When the gear rotates, the melt into the suction chamber two gear tooth, with gear running, the melt from either side int...

14

Jun

Suitable for transportation of crude oil temperature is not higher than 140 ℃, oil, weak alkaline liquid syrup, yeast.I...